From its Perth headquarters, Origo.ag has developed a suite of IoT products and services to remotely monitor and control large broadacre and livestock operations across Western Australia, Victoria, Queensland and New South Wales — one of the world’s largest exporters of grains (including wheat, barley, canola, and oats). Using sensors and cameras as well as internally designed hardware, software, and analytics, Origo helps farmers maximize crop production with pinpoint precision and increase profitability.

Needed: A Higher Level of Ag Planning and Execution

Across hundreds of thousands of square miles — 7 million hectares — farmers in Western Australia (WA) face distinctive barriers, ranging from sandy, nutrient-poor soils and climate extremes to transportation costs and labor shortages. In this often-arid environment, weather monitoring becomes perhaps the most mission critical task. Rainfall, temperature, humidity, and wind conditions can vary from field to field and acre to acre, complicating the challenge of raising crops and livestock.

Across hundreds of thousands of square miles — 7 million hectares — farmers in Western Australia (WA) face distinctive barriers, ranging from sandy, nutrient-poor soils and climate extremes to transportation costs and labor shortages. In this often-arid environment, weather monitoring becomes perhaps the most mission critical task. Rainfall, temperature, humidity, and wind conditions can vary from field to field and acre to acre, complicating the challenge of raising crops and livestock.

“We want to identify the farmer’s limiting factor and help them solve that problem. In this region, water is the limiting factor,” said Annie Brox, founder of Origo.ag, a leading IoT manufacturer and service provider in the Australian agriculture industry. “Factoring in the crop type and field conditions, you need to take advantage of every drop of water available to you. That’s why it’s essential to monitor short-term and long-term weather conditions at a granular level across the entire crop portfolio. The variations and distribution of weather is critical to know — as quickly and completely as possible — so that the farmer can make the right choices about crop growth and on which part of the farm and take the right actions.”

Although Australia is one of the world’s largest grain exporters, farmers in Australia must contend with everything from droughts to convection frost and inversion layers. Without careful monitoring, a single 60-foot boom sprayer can for instance over-fertilize some fields while simultaneously under-fertilize a nearby field. “With so much at stake, farmers can no longer afford to use single strategies and blanket applications,” she said. “They need a higher level of precision in their planning and execution.”

DigiMesh: It Just Works

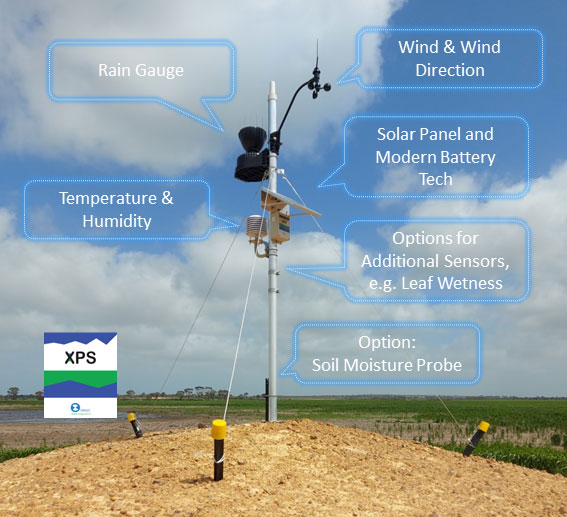

To help its farming customers, Origo.ag has developed an extensive platform of wireless networked solutions that monitor and automate a variety of conditions across hundreds of square miles. The company’s family of weather, climate, and soil stations observe and monitor the microclimate and environmental conditions across fields, barns, and other farm locations.

They measure and report temperature, humidity, rainfall, and wind, as well as calculated measures such as dT, Fire Danger Index (FDI), and the Frost Index and can optionally measure soil moisture and solar radiation. Similarly, other Origo solutions can monitor tank and trough supply and switch control pumps, desalination plants, generators, and valves. Anything that can be switched can be controlled. Cameras can also keep an eye on animals to ensure safety or provide time-lapse images of crops to quickly assess their development.

They measure and report temperature, humidity, rainfall, and wind, as well as calculated measures such as dT, Fire Danger Index (FDI), and the Frost Index and can optionally measure soil moisture and solar radiation. Similarly, other Origo solutions can monitor tank and trough supply and switch control pumps, desalination plants, generators, and valves. Anything that can be switched can be controlled. Cameras can also keep an eye on animals to ensure safety or provide time-lapse images of crops to quickly assess their development.

Tying them all together, Digi XBee RF wireless networking modules are configured in a DigiMesh® network. This peer-to-peer wireless networking protocol creates robust and reliable wireless mesh networks with self-healing, dense network operation and with a very low housekeeping overhead to extend the operational life of battery-dependent devices. DigiMesh networks can cover large areas by relaying messages across multiple nodes, making them scalable for extensive deployments. Data is transmitted with acknowledgments and retries, ensuring successful delivery even in challenging environments.

“In our product designs, we’ve followed the principles of the Toyota Production System and standardized on as many components as possible,” said Brox. “The philosophy extends to our networking choices, too. We like DigiMesh because it’s scalable and reliable. It just works. The whole topology is robust, configurable, and self-healing. Other mesh networks force you to do a lot of this work yourself, but DigiMesh doesn’t require all of that manual setup and maintenance.”

A Smarter Way to Farm

Once the networked Origo devices are deployed in strategic locations, farmers can use the company’s XDASH dashboard on any device to monitor the latest weather information, spot trends, and make smarter decisions about how to best manage their crops and livestock. “There are no cables — everything is in the box and every product is based around the same components. Origo.ag Service Partners and Resellers can set up a weather station in 20-30 minutes and it just works right away,” Brox noted.

While the data volumes aren’t large, the transmission frequency is high — as often as once every one to five minutes. “The value is that the data can flow from the station to the back-end database and front-end to the user’s phone or computer in seconds,” she said, “and we can use that same connection to remotely control devices such as valves, flow controls, and feeders. We can show current tank levels or schedule trough replenishments. In addition, we develop custom data warehouses so our customers can analyze their data through XDASH or export it to spreadsheets or business intelligence tools.”

In Brox’s estimation, Origo’s solutions offer more value that initially meets the eye. “Our farmers are, ultimately environmentalists,” she said. “They want to act sustainable. They care about soil conditions and crop rotations. They’re looking at weather and climate patterns and asking, ‘How do I help feed the world and run this farm in the face of this variability? How can I reduce the environmental impact of farming and eliminate wasted water usage?’ I’m proud that Origo is playing an important role in addressing these important challenges in Western Australia.”

Next Steps