When you have an idea to build a product to take to market, it’s a bit like that moment when racing cars position themselves at the starting line, engines revving, waiting for the flag to drop. You need to be ready for the race, and you need to have all components in place and firing on all cylinders, or you’re simply not going to win.

We liken this analogy to the process of designing embedded products for several reasons. It points to how critical it is to clear away any obstacles to success. You don’t want anything to slow down your process for avoidable reasons, like not having a clear vision of your end goal, or not having the right resources to be successful. We’ll cover how critical that is in this article.

Additionally, the racing car analogy is a reminder of how competitive the marketplace is. While it’s not always true, it’s very often the case that the first to market with a really keen technology is the one that’s going to win. No one ever said the best technology ever won!

So let’s talk about the starting point for embedded designs, how to clear away the friction and get obstacles out of the way. Naturally, we have some recommendations for intelligent short-cuts you can make to ensure your success.

Embedded Design Strategy: Choose Your Starting Point Wisely

Developer teams have a critical decision to make immediately upon launching the planning and design process: Should you use a pre-made module or embark on a chip-down solution?

To answer this question, you need to review a number of important factors:

- Do you have the engineering resources on staff (and available) to build from scratch?

- If you build your own module, can you get to market within your desired timeline?

- If your initial assumption is that it is cheaper to build your own module, have you validated that assumption?

The following subsections cover each of these topics, with the key considerations.

Engineering Resources for Embedded Design Projects

It is important to seriously evaluate your staff resources, as this is one of the biggest miscalculations we see development teams make. The scope of the project is almost always larger than initially believed during that exciting ideation period when the project is identified as viable.

It is important to seriously evaluate your staff resources, as this is one of the biggest miscalculations we see development teams make. The scope of the project is almost always larger than initially believed during that exciting ideation period when the project is identified as viable.

Why does this happen? We’ve found that the rough thumbnail sketch development teams make of the design, build and production cycle very often leaves out some key considerations. These include:

- Whether the team has built this particular type of product design before.

- Whether all other projects can be set aside to make room for the new project to take top priority – or better yet, the only priority.

- Whether you have thought of absolutely everything you will need to incorporate into the product design for it to be successful – and therefore the expertise needed. For example, does your team have deep experience in embedded security?

Development Timeline and Go-to-Market Goals

If there is no particular urgency for your team to complete your project, you can skip over reading this section. But you would be a rare breed. And we do want to provide a word of caution that projects without a defined timeline tend to be some of the most expensive, as they often involve developer teams working full time – but not at peak efficiency – for a lengthy period, instead of focusing their efforts effectively for a shorter period.

If there is no particular urgency for your team to complete your project, you can skip over reading this section. But you would be a rare breed. And we do want to provide a word of caution that projects without a defined timeline tend to be some of the most expensive, as they often involve developer teams working full time – but not at peak efficiency – for a lengthy period, instead of focusing their efforts effectively for a shorter period.

For most projects, getting to market sooner rather than later is important. Not only do you stand a better chance of gaining advantage over competitive products, but the sooner you get to market the sooner you realize revenue.

So, given the assumption that timely is better, let’s return to the racing car analogy. If you want to get on that track and race for the finish line, you’ll want to consider the best ways to build the fastest racing car in the shortest timeframe possible. You can get there much faster if you start with some pre-built, pre-tested components developed by a manufacturer that specializes in designing those components and has the long-term commitment to maintaining them.

Evaluating the Cost of Building vs. Buying

As mentioned, it’s important to fully validate the assumption that building your own module is a less expensive proposition than starting with a pre-built module.

As mentioned, it’s important to fully validate the assumption that building your own module is a less expensive proposition than starting with a pre-built module.

Another one of the pain points we repeatedly hear – in addition to miscalculating the engineering talent needed – is underestimating the resources needed to support the full product lifecycle. As developer teams complete their first prototypes and begin the process of testing and iterating on the design, it often becomes clear what a long journey is ahead to ensure its success. Taking a modular approach instead – and purchasing your SOM – can put you light years ahead on your design, therefore saving an enormous amount of cost in the development cycle.

Additionally, it’s important to remember that you are responsible for maintaining the product you deliver to customers. This means you will need to provide firmware updates and support ongoing enhancements, security and bug fixes, which will impact your company’s bottom line for years to come.

Benefits of a Modular Design Based on Digi SOMs

Not sold yet on starting with a module, instead of building from scratch? Here we will cover some additional key advantages.

Not sold yet on starting with a module, instead of building from scratch? Here we will cover some additional key advantages.

- The fact that the processor is already complete and tested makes it easier to design the application board. Some parts of that circuit can be deduced from the reference design in the starter kit, which allows the application board to be designed even more quickly and reliably.

- The key software drivers are delivered with the module BSP (board support package) ready to be used immediately, so software development can start on day one since the target platform is already available.

- As a result, real parallel engineering can take place. Performance tests are often necessary before a final design decision is made. This can be conducted with modules, reducing development time.

With Digi embedded modules, you not only start with a well-tested device, but you have an entire development platform available to you. That includes sophisticated software, code libraries, development tools, programming compatibility tools, documentation and more.

In our white paper, we go into more depth into these topics to help teams perform the extensive evaluation needed to make the best build vs. buy decision – from describing some of the key disciplines required of development teams, to a discussion of the critical security considerations to important things to know as you prepare to productize your design and take it through manufacturing to mass production.

IoT Devices for Rapid Time-to-Market

Take a brief tour of the device families that support rapid modular development in a world where you can’t afford to have product development tied up in certification challenges.

Ultra-compact, Highly Integrated System-on-Module Solutions

Digi’s system-on-modules (SOMs) offer multiple embedded wireless solutions including pre-certified 802.11a/b/g/n/ac, Bluetooth and options to add cellular. Built on the latest processors, such as the NXP i.MX6 UL, i.MX 8X, i.MX 8M Nano and i.MX 8M-Mini, Digi SOMs provide device security for connected IoT applications, and you can accelerate parallel software development with Digi's support for embedded Android and Linux development environments including Yocto Project.

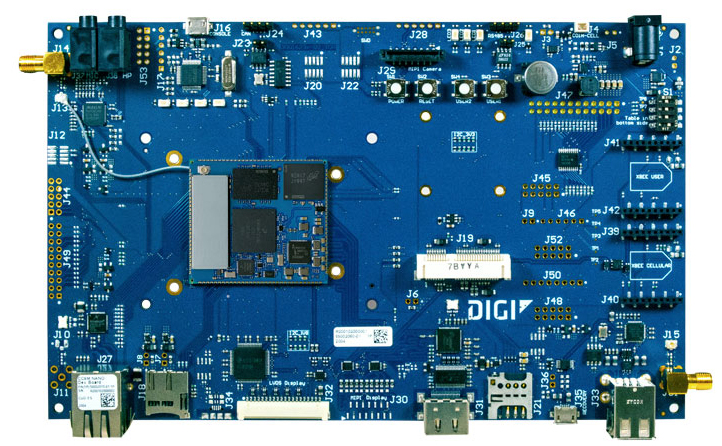

Digi ConnectCore® 8M Nano System-on-Module

Versatile, Off-the-Shelf SBCs

Borne from our SOMs, Digi's line of compact, cost-effective and versatile off-the-shelf single board computers (SBCs) offer significantly reduced time-to-market by virtually eliminating the traditional risk, effort, and complexity of custom board designs without sacrificing flexibility or capabilities. Digi SBCs support various ARM-core processors and controllers, and multiple wireless interfaces.

Digi ConnectCore® 8M Nano Development Board

For our NXP SOM-based SBCs, we also provide complete schematics, Gerber files, bill of materials and resources so developers can rapidly create their own carrier boards.

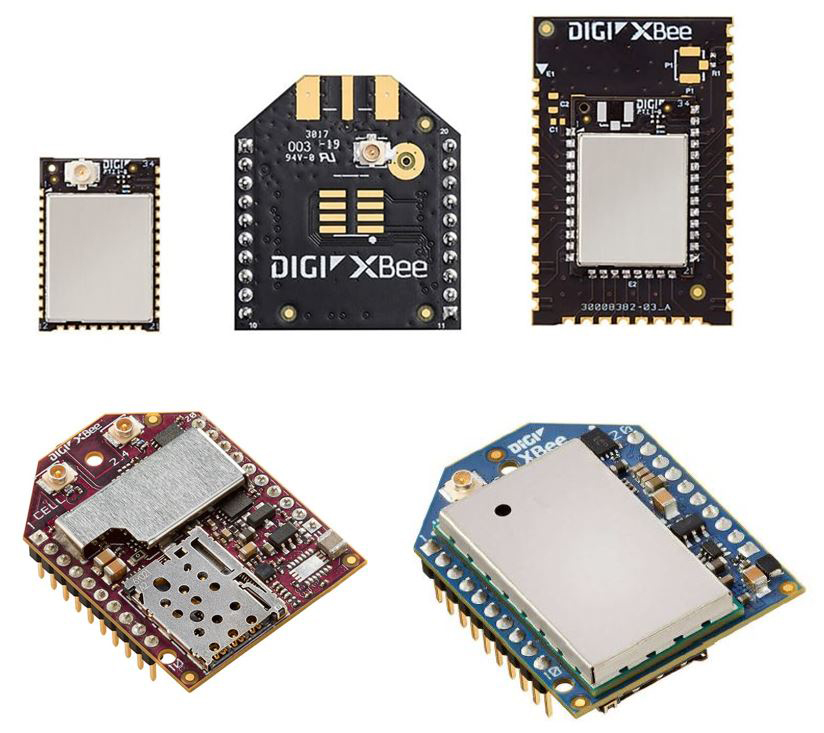

The Digi XBee Ecosystem

Digi XBee® RF modules provide wireless connectivity in a range of protocols and form factors to support today's low-power IoT applications. Easy-to-deploy, pre-certified, and configurable using Digi XCTU® and the XBee mobile app, these low-cost modules support all of your wireless design requirements.

Digi XBee Form Factors

Digi XBee also offers the easiest way to integrate cellular connectivity into an OEM device. With the introduction of 3GPP standards like LTE Cat 1, LTE-M and NB-IoT, as well as older standards like 3G HSPA/GSM, Digi has the cellular modem for your design. Digi XBee cellular modems provide easy cellular connectivity without having to go through a costly FCC or carrier end-device certification process. The XBee Ecosystem includes RF modules in multiple form factors for embedded IoT designs and pre-certified embedded cellular connectivity for rapid deployment.

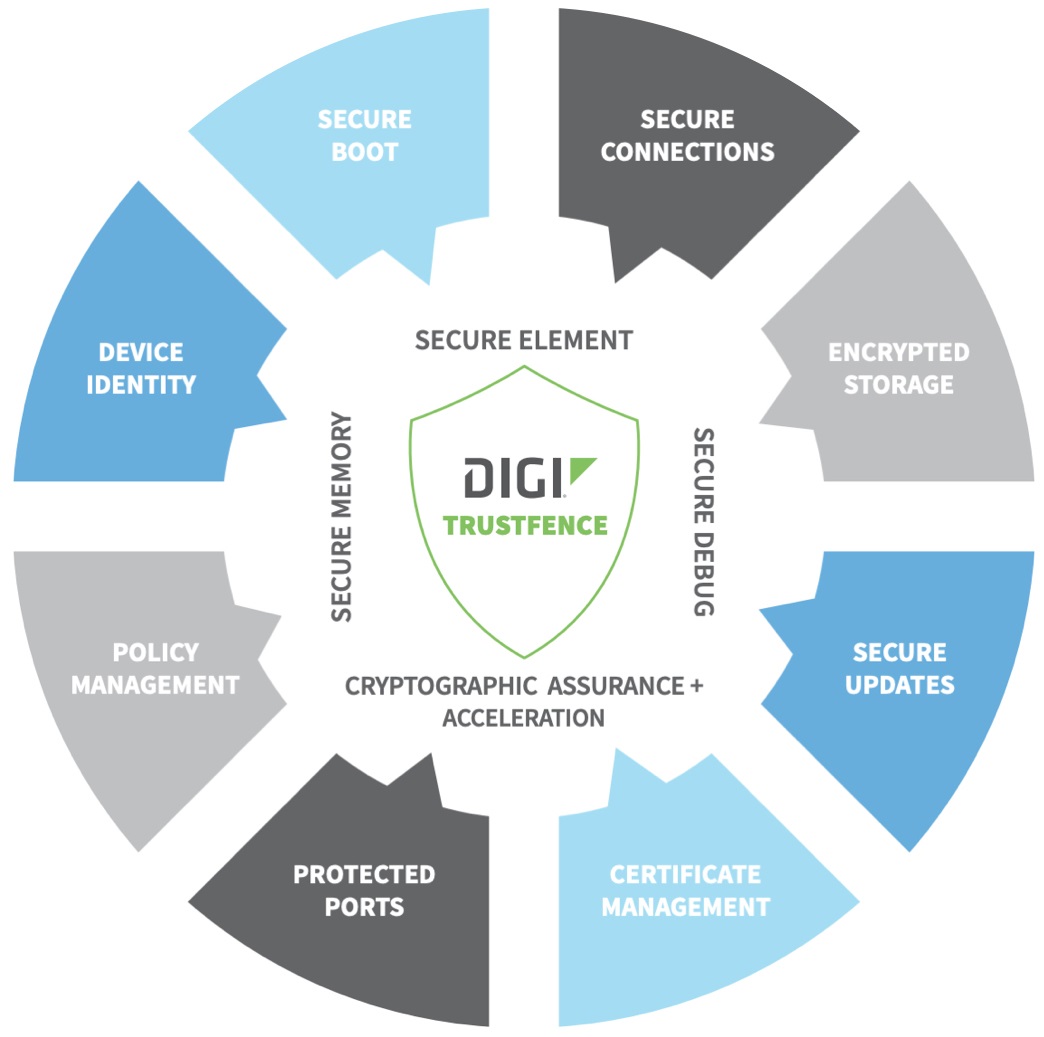

Digi TrustFence for Embedded Design Security

Embedded security is a critical design component for a growing number of connected IoT applications and devices. The built-in security of Digi TrustFence® gives you immediate access to critical features including secure connections, authenticated boot, encrypted data storage, access-controlled ports, secure software updates, and seamless integration of the dedicated on-module Secure Element (SE).

Many of Digi’s customers operate in highly regulated industries. Digi has taken an industry-leading position around the adoption of standards and other relevant security certifications such as HIPAA, FIPS 140-2, and NIST, as well as helping customers to comply with certifications like PCI-DSS for retail and FDA for medical devices.

Ready to plan your next connected product? Contact us to start the conversation.