What makes an automated device like a motion-activated light switch different from an IoT-connected device that does the same thing? In a word: data. With an IoT-connected device, when a sensor detects motion and an actuator turns on a light, those actions are captured as data and sent to the cloud or a data center for recording and analysis. And where there’s data, there needs to be an

IoT architecture that tells the data where to go, what format to use, how to get there and what actions to take based upon this data.

In this blog post we’ll offer a quick overview of IoT architecture and look at how it guides the flow of data to and from devices and data hubs.

Data Flow: From the Edge to the Server/Cloud

IoT system architecture is often described as a four-stage process in which data flows from sensors attached to “things” through a network and eventually on to a corporate data center or the cloud for processing, analysis and storage.

In the Internet of Things, a “thing” could be a machine, a building or even a person. Processes in the IoT architecture also send data in the other direction in the form of instructions or commands that tell an actuator or other physically connected device to take some action to control a physical process. An actuator could do something as simple as turning on a light or as consequential as shutting down an assembly line if impending failure is detected.

Let’s review this IoT architecture one stage at a time.

STAGE 1: Sensors and Actuators

The process starts with sensors and actuators, the connected devices that monitor (in the case of sensors) or control (in the case of actuators) some “thing” or physical process. Sensors capture data regarding the status of a process or an environmental condition, such as temperature, humidity, chemical composition, fluid levels in a tank, fluid flow in a pipe, or the speed of an assembly line as well as much more.

The process starts with sensors and actuators, the connected devices that monitor (in the case of sensors) or control (in the case of actuators) some “thing” or physical process. Sensors capture data regarding the status of a process or an environmental condition, such as temperature, humidity, chemical composition, fluid levels in a tank, fluid flow in a pipe, or the speed of an assembly line as well as much more.

In some cases, a sensor might detect a condition or event that requires an almost immediate response so that an actuator can perform remediation actions in real time, for example, adjusting the flow rate of a fluid, or the movements of an industrial robot. In these situations, very low latency between the sensor and analysis/triggered actuator is required. To avoid the delay of a round-trip of data to the server, analysis of data to determine failure and sending of control to the “thing”, this critical processing is performed in close proximity to the process being monitored or controlled. This “edge” processing can be performed by a system on module (SOM) device such as a Digi ConnectCore® module and/or a Digi Cellular Router with Python.

STAGE 2: Internet Gateways and Data Acquisition Systems

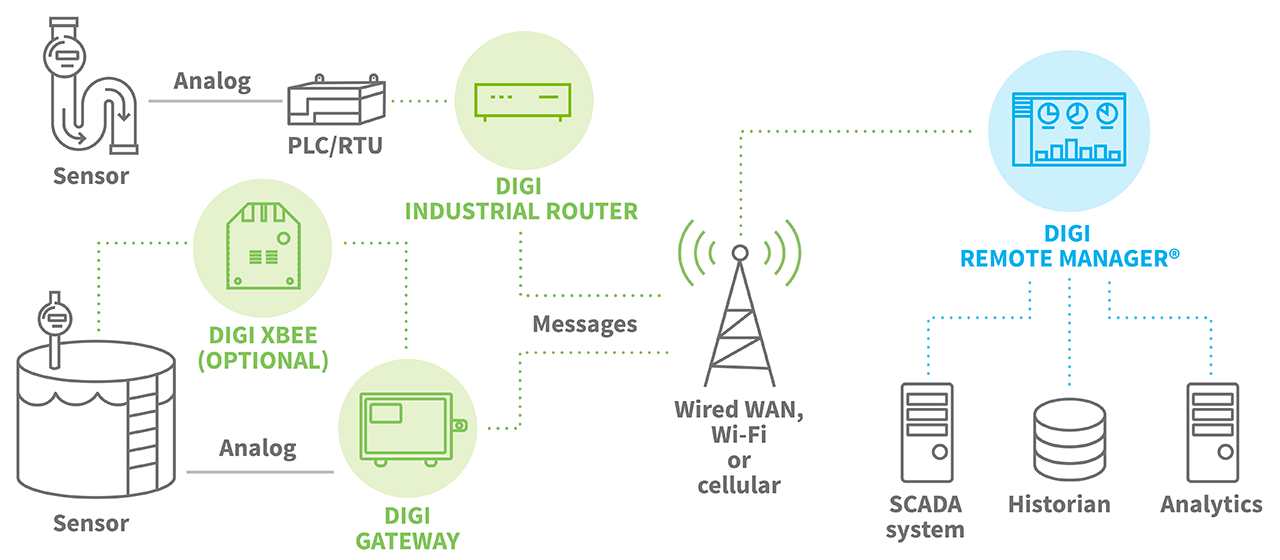

A data acquisition system (DAS) collects raw data from the sensors and converts it from analog into digital format. The DAS then aggregates and formats the data before sending it through an Internet gateway via wireless WANs (such as Wi-Fi or Cellular) or wired WANs for the next stage of processing.

A data acquisition system (DAS) collects raw data from the sensors and converts it from analog into digital format. The DAS then aggregates and formats the data before sending it through an Internet gateway via wireless WANs (such as Wi-Fi or Cellular) or wired WANs for the next stage of processing.

At this point, the volume of data is at its maximum. The quantities can be huge, especially, for example, in a factory setting where hundreds of sensors may be gathering data simultaneously. For that reason, the data is also filtered and compressed to an optimum size for transmission.

Discover how Enlazza Uses Digi RM to Securely Manage Fleet of Digi Routers

"With our HNS connecting to Digi Remote Manager, we’ve solved the problem of reaching Digi Routers using private connections on IPv4"

Read Story

STAGE 3: Pre-processing: Analytics at the Edge

Once the IoT data has been digitized and aggregated, it will need processing to further reduce the data volume before it goes to the data center or cloud. The edge device may perform some analytics as part of the pre-processing. Machine learning can be very helpful at this stage to provide feedback into the system and improve the process on an ongoing basis, without waiting for instructions to come back from the corporate data center or cloud. Processing of this type will generally take place on a device in a location close to where the sensors reside, such as in an on-site wiring closet.

Once the IoT data has been digitized and aggregated, it will need processing to further reduce the data volume before it goes to the data center or cloud. The edge device may perform some analytics as part of the pre-processing. Machine learning can be very helpful at this stage to provide feedback into the system and improve the process on an ongoing basis, without waiting for instructions to come back from the corporate data center or cloud. Processing of this type will generally take place on a device in a location close to where the sensors reside, such as in an on-site wiring closet.

STAGE 4: In-depth Analysis in the Cloud or Data Center

At Stage 4 in the process, powerful IT systems can be brought to bear to analyze, manage, and securely store the data. This usually takes place in the corporate data center or in the cloud, where data from multiple field sites/sensors can be combined to provide a broader picture of the overall IoT system and deliver actionable insights to both IT and business managers. A company may have operations in different geographies and IoT data can be analyzed to identify key trends and patterns, or to spot anomalies.

At Stage 4 in the process, powerful IT systems can be brought to bear to analyze, manage, and securely store the data. This usually takes place in the corporate data center or in the cloud, where data from multiple field sites/sensors can be combined to provide a broader picture of the overall IoT system and deliver actionable insights to both IT and business managers. A company may have operations in different geographies and IoT data can be analyzed to identify key trends and patterns, or to spot anomalies.

At this level, industry-specific and/or company-specific applications can be used to perform in-depth analysis and apply business rules to determine whether action needs to be taken. The incoming data may indicate desirable changes to device settings or other ways to optimize the process, forming a loop that facilitates constant improvement. Stage 4 also includes storage in a data warehouse, both for record keeping and for further analysis.

A Process Needs a Platform

In addition to the four-stage IoT architecture, it’s also important to consider the IoT platform, which provides connectivity between the stages. The structure of the platform defines the nuts-and-bolts specifics of the data traffic. It determines what data goes where and how much processing is performed at each stage. An IoT platform can be customized to a greater or lesser degree, depending on how specialized the system needs to be.

As an example, IoT for streetlights might be very similar from one city to another, anywhere in the world, whereas the sensors and actuators on a 3-D printer for fabricating medical devices might be one of a kind.

Learn More About IoT Management

With a solid platform and well-designed architecture, IoT can improve safety, efficiency and productivity in virtually every industry. The right IoT platform can provide the tools you need for success.

To learn about the considerations for IoT platforms and how you can build your own IoT architecture, watch our video, Top 5 IoT Platform Requirements.

Digi Remote Manager® is a secure, sophisticated IoT device management solution that gives you a command center to configure, deploy, monitor and manage your IoT project. Learn more in our blog post, What Is IoT Device Management?

The IoT’s Best Is Yet to Come

While the IoT is already in use in numerous consumer, commercial, industrial and infrastructure applications, we can expect to see IoT systems appearing in much greater numbers and in a greater variety of use cases in the very near future.

Planning your IoT project? Reach out to start the conversation.

Next Steps